JSJM Technology offers comprehensive cap mold manufacturing services to meet all your needs. As a leading manufacturer in the industry, we provide end-to-end solutions, from design and engineering to production and assembly. With our comprehensive services, you can trust that your cap mold project is in capable hands. We utilize advanced technologies, such as CNC machining and injection molding, to deliver high-quality cap molds that meetthe highest standards of precision and performance. From the initial concept to the final product, we are dedicated to delivering excellence at every step.

Designed to minimize material use, our cost-effective cap mold saves waste and lowers production costs. By having precise runner system designs and cavity design in our molds, we can limit the amount of material consumed while maintaining a constant and dependable caps production. When you choose to work with us, you will reduce your raw materials costs significantly without your caps’ quality and performance deteriorating in any way.

The design of our cap mold is very much innovative and it makes a provision for customization that is unrivaled and versatility. We comprehend that different products necessitate diverse designs of caps; consequently, our molds accord an easy opportunity for altering the size, shape or even features of caps. Our cap mold can be adjusted to accommodate any type of screw up cap, flip-top cap or another kind depending on your preference thus making you come up with unique product that will stand out among others in the market.

To achieve superior quality and consistency, use our cap mold. It’s precision engineered and manufactured to close tolerances ensuring accurate molding of caps resulting in even dimensions, glossy surfaces and dependable performance. With one or multiple cavity molds, our cap mold gives you a guarantee for consistent high quality output that conforms to your product specifications.

It is made to last, durable, and has longevity. It is made from high-end materials with precision engineering that can stand the test of time during continuous manufacturing, thus giving consistent performance over an extended period. By going for our cap mold, you ensure a production process that’s more efficient, reduces downtime and lower costs in caps making but still maintaining quality.

JSJMO is an injection mold manufacturer based in China. With our in-house precision manufacturing equipment,we areable to offer multiple services: product design,mold design,mold making and injection molding.

We have more than 10,000+ ㎡ of standardized industrial plants, more than tens of millions of professional equipment!We attach great importance to the training of employees and the reserve of talents. We have more than 50+ professional and technical talents, and more than 100 ordinary operating technicians! Statistics from the third party, our annual export volume is more than 10 million US dollars.Welcome to contact us anytime and you can trade with us with confidence!

With over two decades of experience in the industry, JSJM Technology has mastered the art of injection molding.Our extensive knowledge and expertise ensure that we deliver top-quality products that meet the highest standards.

At JSJM Technology, we understand that every project is unique. That's why we offer customized solutions tailored to your specific requirements. Whether you need a small batch of molds or a large-scale production run, we have the capabilities to meet your needs.

Quality is our top priority at JSJM Technology. We have rigorous quality control measures in place to ensure that every product meets our strict standards. Our commitment to quality ensures that you receive the best possible results for your projects.

We believe that customer service is just as important as the quality of our products. That's why we offer personalized support and assistance throughout the entire process. Our goal is to make your experience with JSJM Technology as smooth and hassle-free as possible.

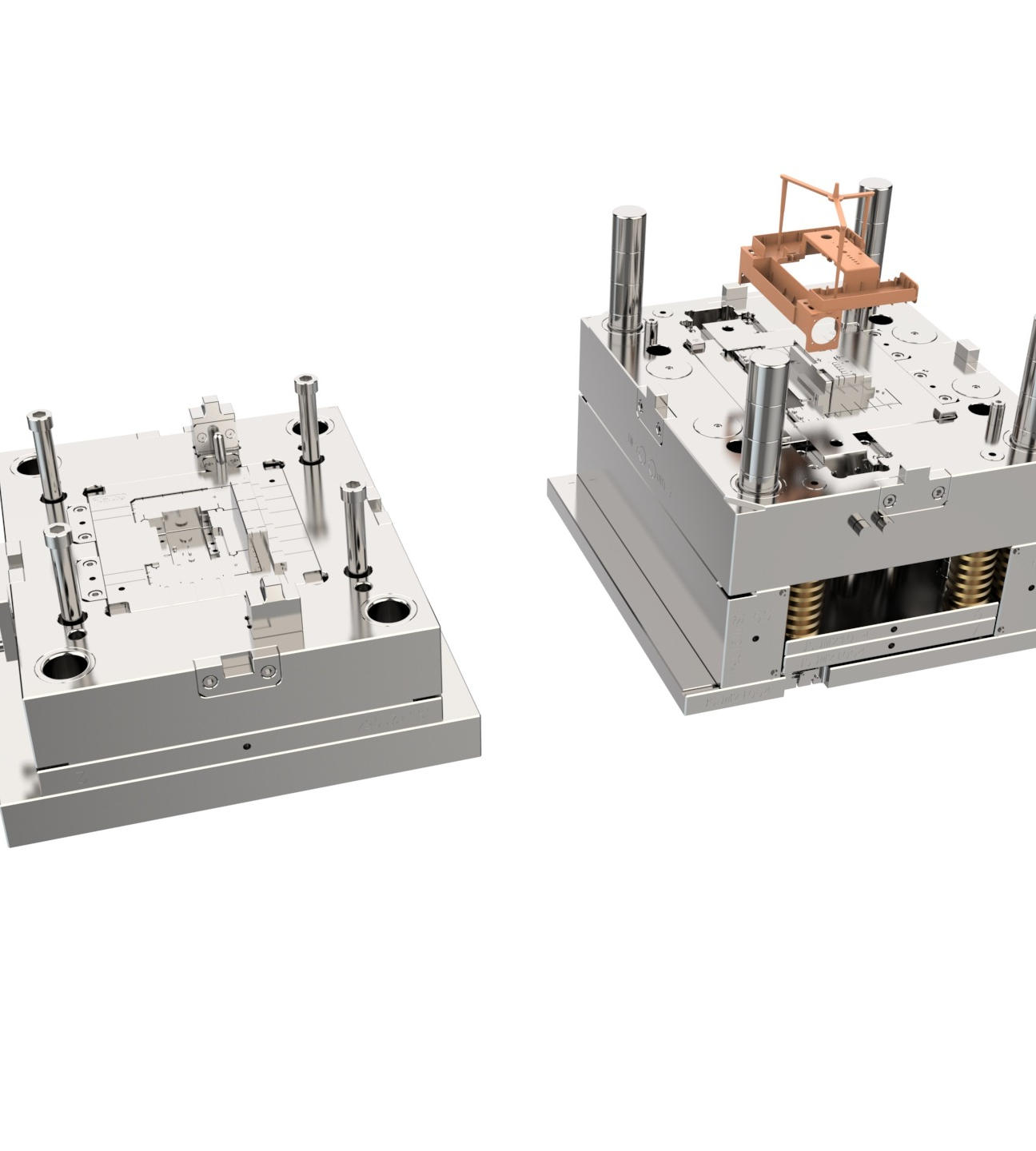

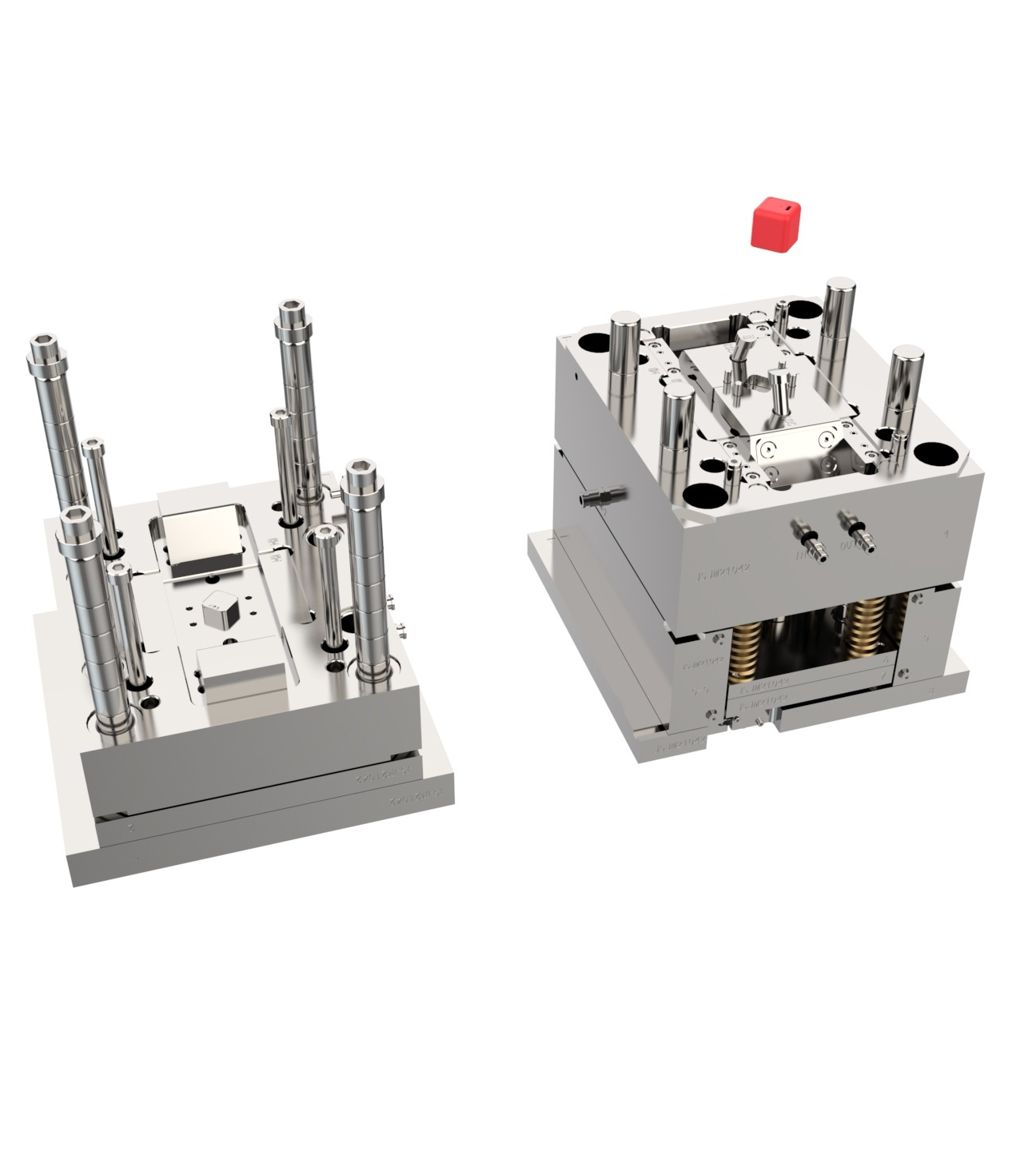

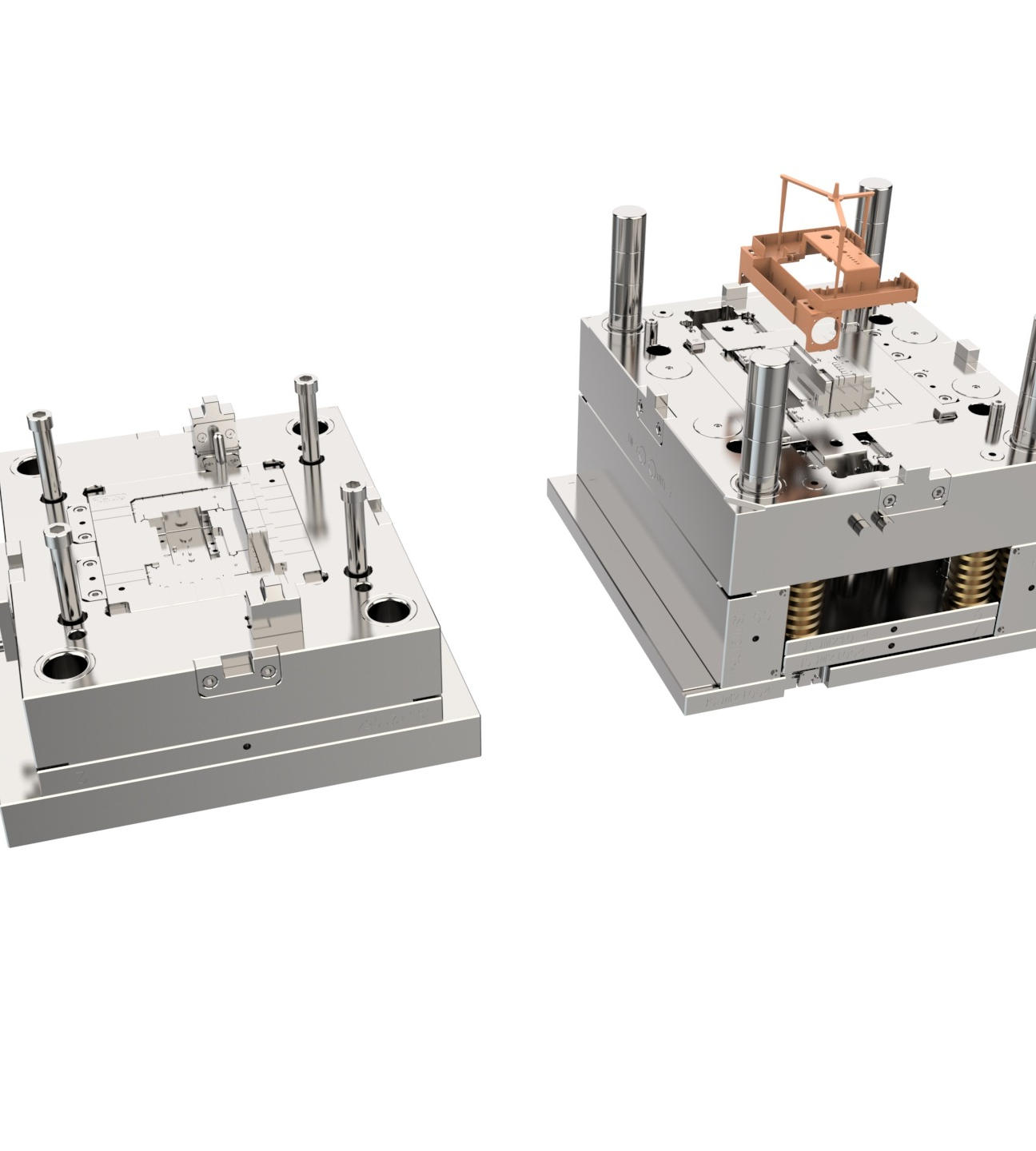

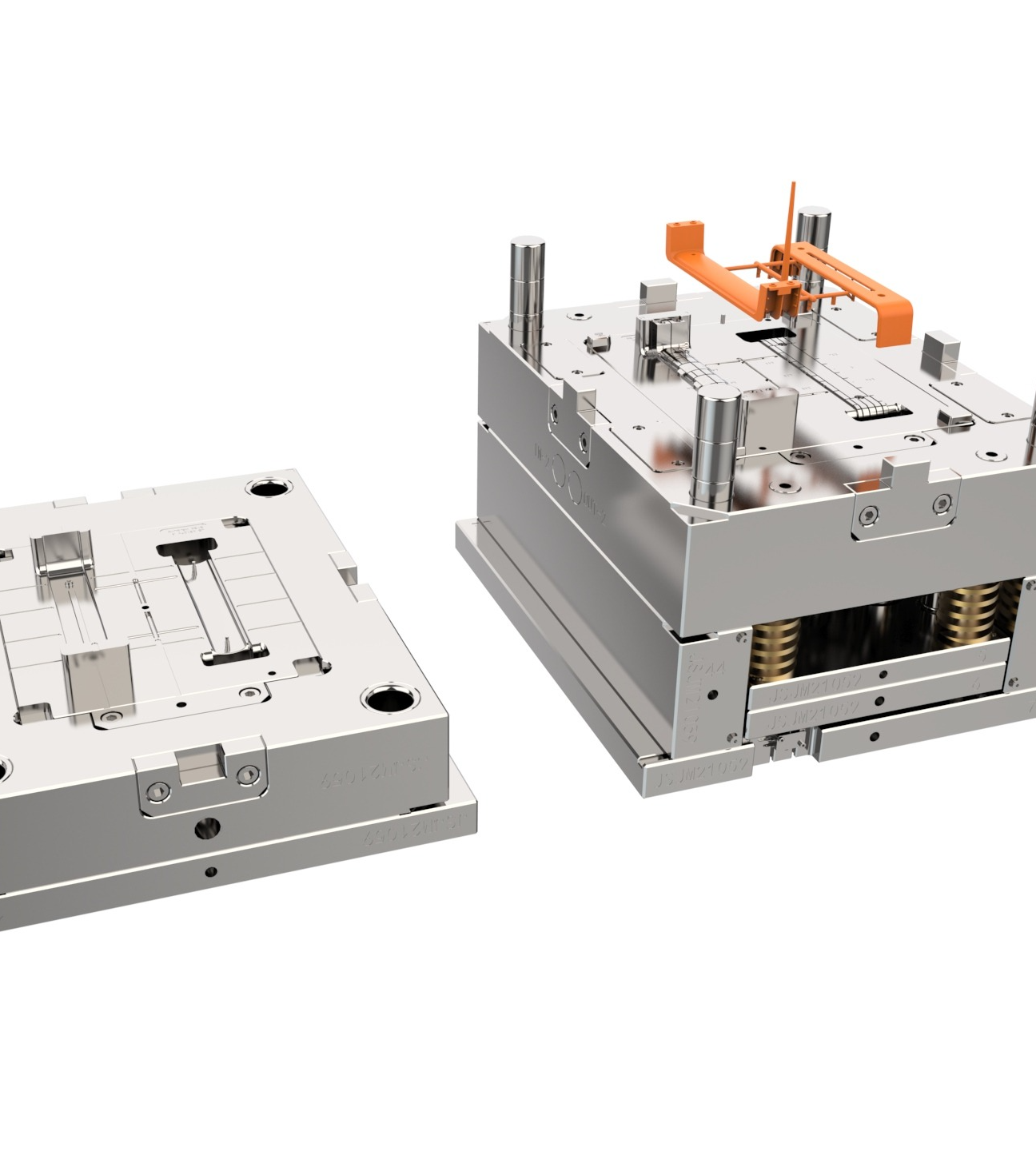

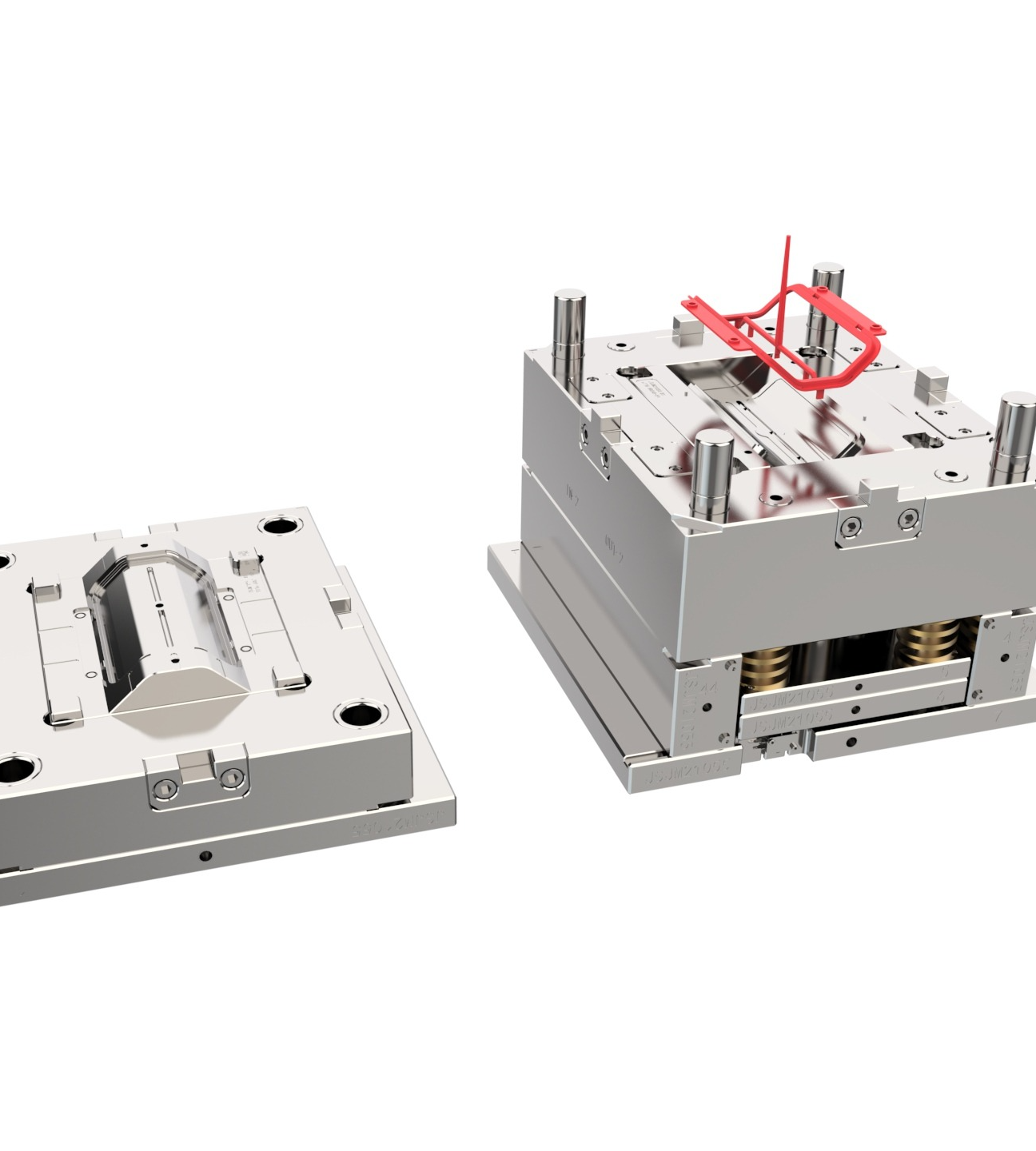

A cap mold is a specialized tool used in the injection molding process to create plastic caps. It consists of two halves that form a cavity where molten plastic is injected under high pressure to take the shape of the cap.

Cap molds are typically made from steel or aluminum due to their durability and ability to withstand the high temperatures and pressures involved in the injection molding process.

At JSJM Technology, we adhere to strict quality control measures throughout the cap mold manufacturing process. This includes using high-quality materials, precise machining techniques, and thorough testing to ensure that our cap molds meet the highest standards of quality and performance.

Yes, JSJM Technology specializes in custom cap mold design and manufacturing. We work closely with our clients to understand their unique requirements and provide tailored solutions that optimize production efficiency and product quality.

At JSJM Technology, we believe in building long-term relationships with our clients. We offer comprehensive after-sales support, including technical assistance, maintenance advice, and troubleshooting to ensure that our clients get the most out of their cap molds.

Copyright © ©Copyright 2024 JSJM Technology Co., Ltd. all rights reserved - Privacy policy