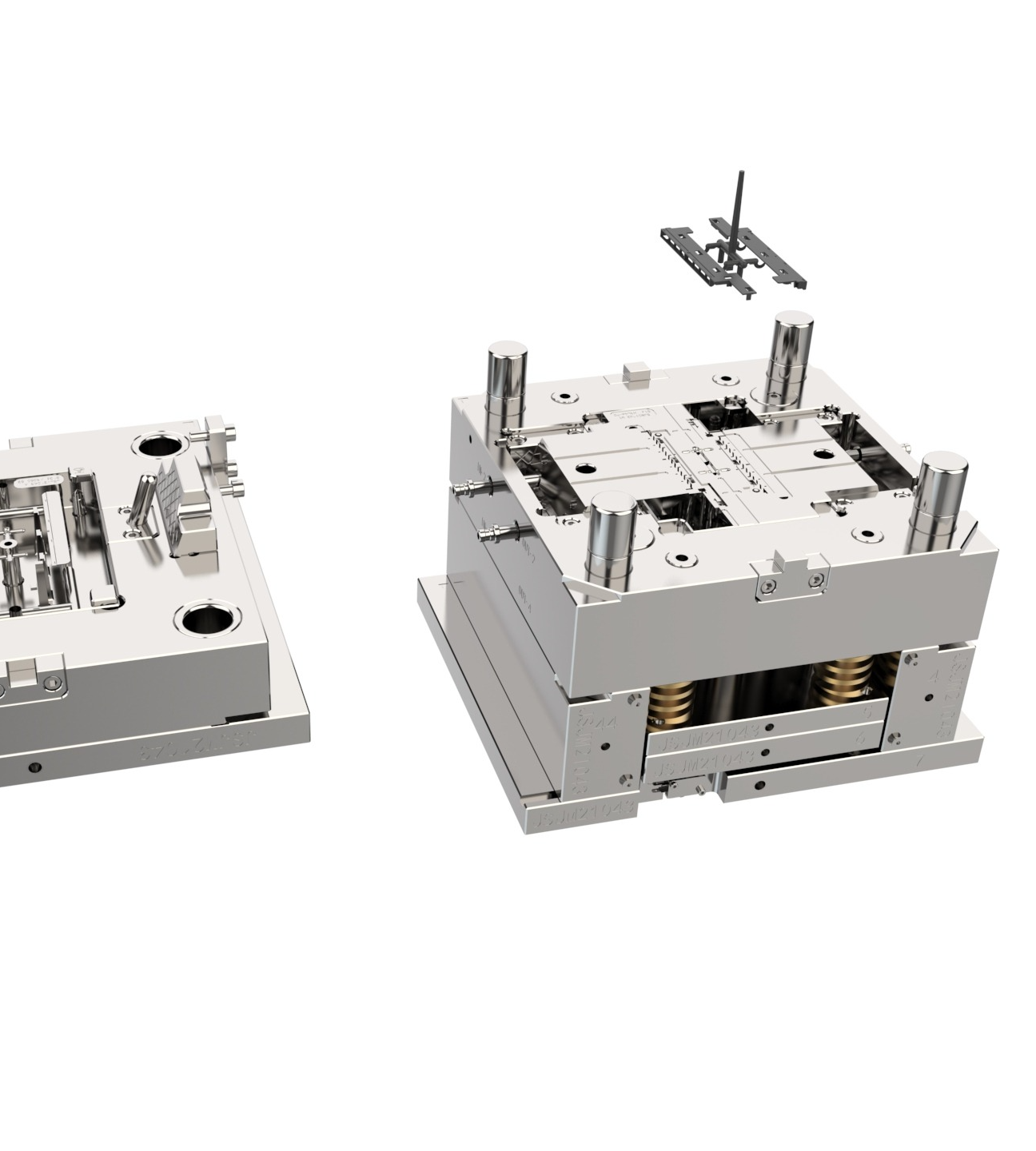

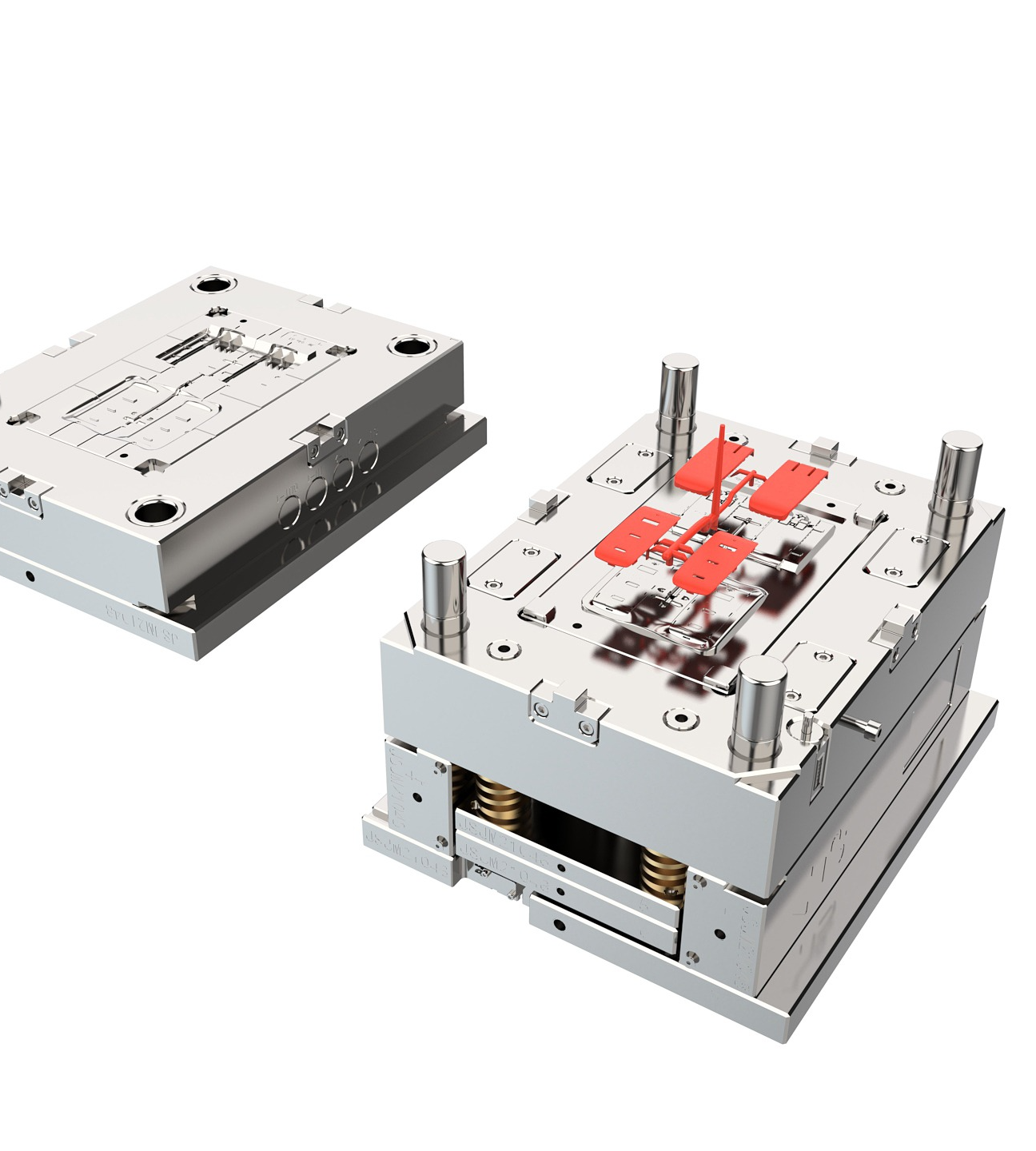

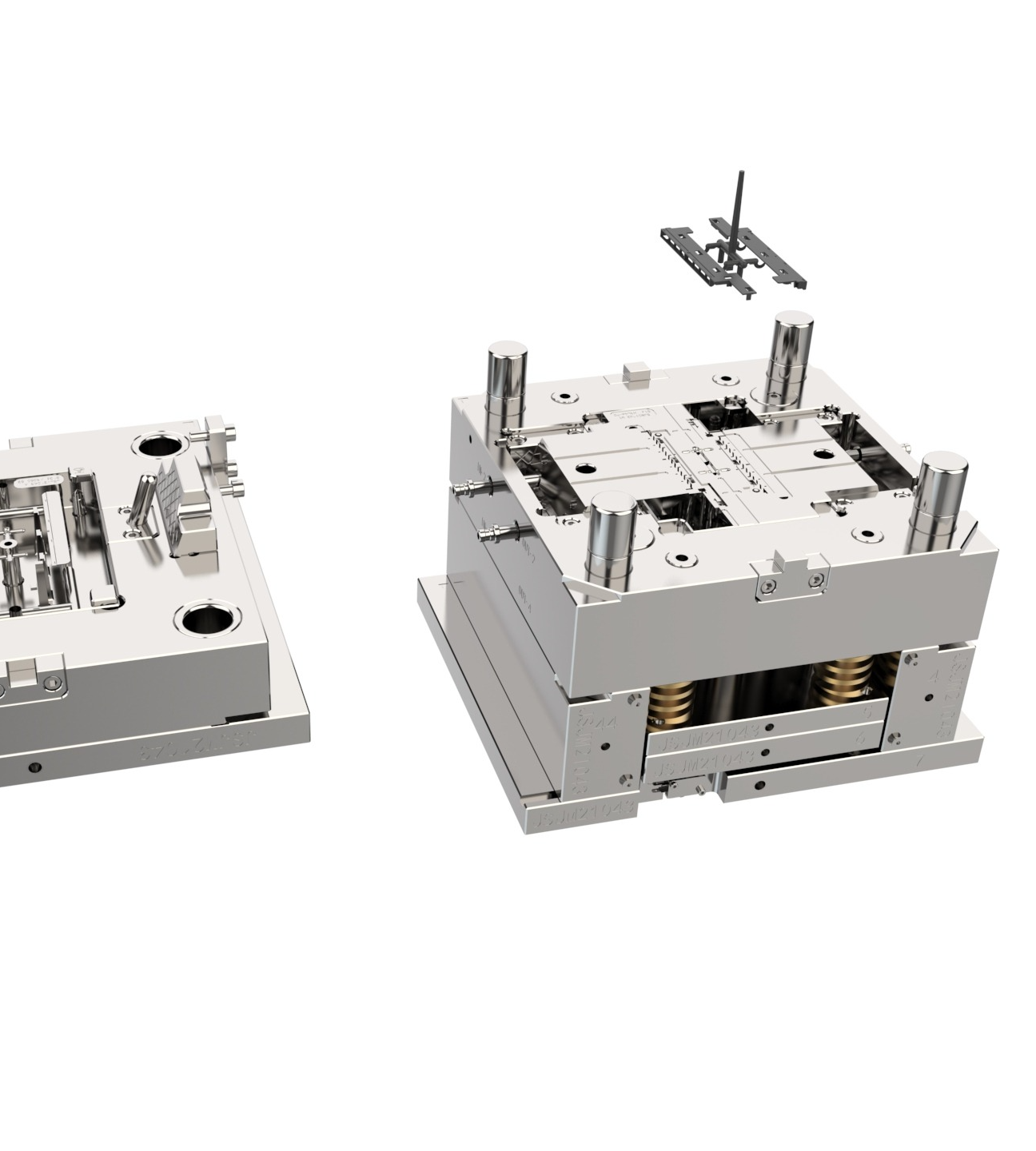

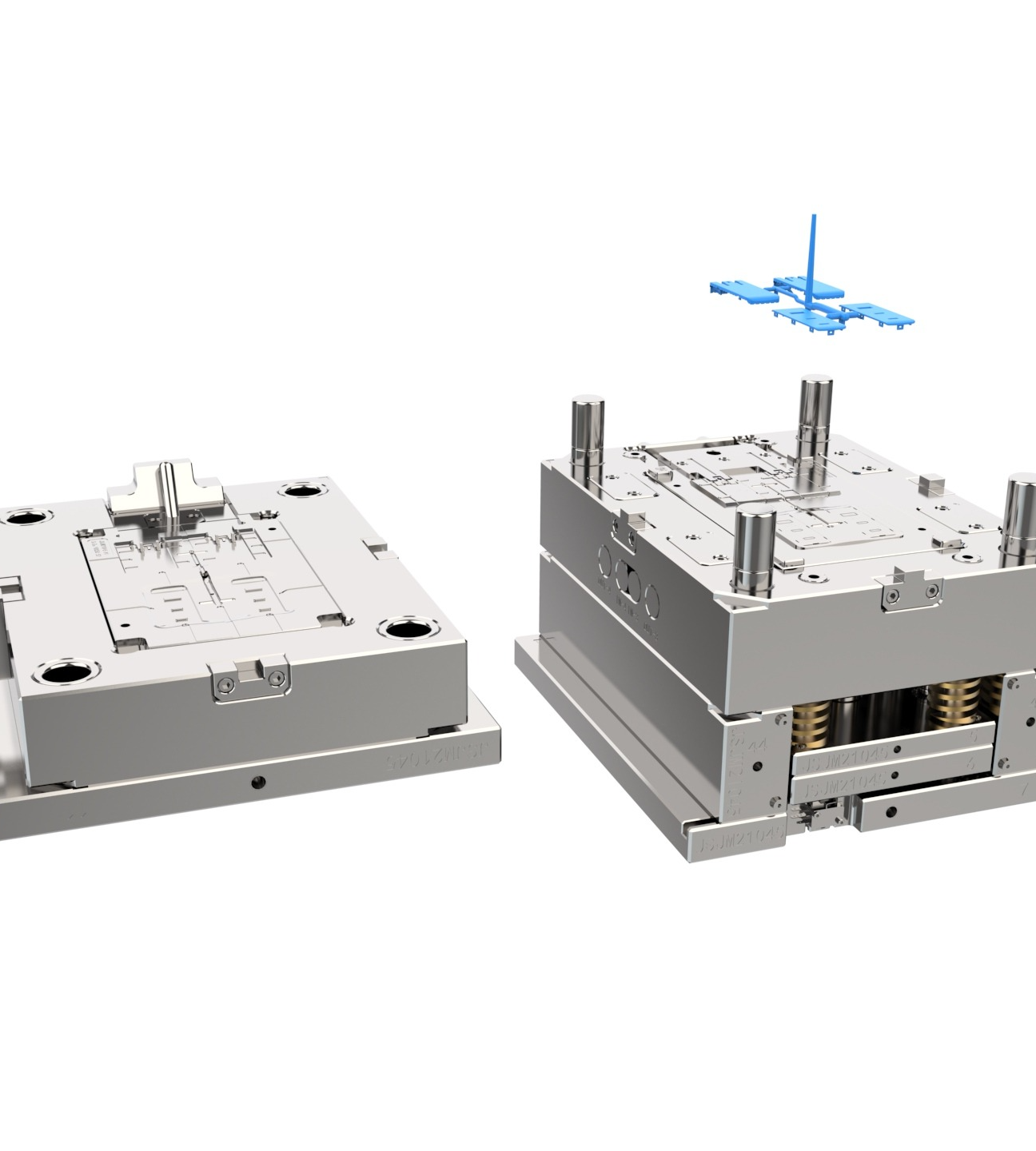

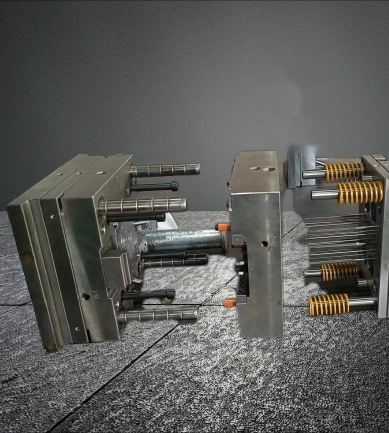

Our extensive selection of injection molds caters to a wide range of applications. From small intricate parts to large-scale components, we have the expertise to deliver molds that meet your unique specifications. Our injection molds are designed and manufactured using advanced techniques and state-of-the-art machinery, ensuring precision, durability, and optimal performance. Whether you require single-cavity molds, multi-cavity molds, or complex molds with intricate features, JSJM Technology has the capabilities to fulfill your needs.

In order to improve the efficiency and productivity of our injection molding process, JSJM Technology heavily relies on automation. Our molds are fitted with automated systems for material handling, loading and unloading thereby reducing manual labor. This enhances not only faster production but also makes the process safer and minimizes mistakes. By using our automatic injection molds, you can obtain superior throughput as well as improved quality control.

Being a flexible process of manufacturing, injection moulding allows for rapid prototyping and low-volume production. JSJM Technology provides quick turnaround times for prototype injection moulds to enable you test your product designs and make necessary improvements before embarking on mass production. We design our molds with the possibility of changes and amendments so that your goods will match exactly what you want them to be like.

We at JSJM Technology appreciate that every product has its own performance. This is the reason we provide specialized options for our injection molds like cooling channels, inserts and ejector pins to optimize the functioning of your parts. Our molds are uniquely designed in accordance with your requirement for instance, shorter cycle times, better surface finishes and improved functionality of parts among other things. Through these custom injection moulds you will have attained the best possible performance of your products.

A sustainable technique in molding that saves resources and eliminates waste. Sustainability is our major prioritized at JSJM Technology with regard to all the designs of our injection mold. Our molds have been optimized so as to reduce material usage and also minimize energy consumption while the molding process is going on. Selecting our injection molds can enable you make parts for your products with high quality and aid in shaping a more sustainable future.

JSJMO is an injection mold manufacturer based in China. With our in-house precision manufacturing equipment,we areable to offer multiple services: product design,mold design,mold making and injection molding.

We have more than 10,000+ ㎡ of standardized industrial plants, more than tens of millions of professional equipment!We attach great importance to the training of employees and the reserve of talents. We have more than 50+ professional and technical talents, and more than 100 ordinary operating technicians! Statistics from the third party, our annual export volume is more than 10 million US dollars.Welcome to contact us anytime and you can trade with us with confidence!

With over two decades of experience in the industry, JSJM Technology has mastered the art of injection molding.Our extensive knowledge and expertise ensure that we deliver top-quality products that meet the highest standards.

At JSJM Technology, we understand that every project is unique. That's why we offer customized solutions tailored to your specific requirements. Whether you need a small batch of molds or a large-scale production run, we have the capabilities to meet your needs.

Quality is our top priority at JSJM Technology. We have rigorous quality control measures in place to ensure that every product meets our strict standards. Our commitment to quality ensures that you receive the best possible results for your projects.

We believe that customer service is just as important as the quality of our products. That's why we offer personalized support and assistance throughout the entire process. Our goal is to make your experience with JSJM Technology as smooth and hassle-free as possible.

Injection molding is a manufacturing process used to create plastic parts by injecting molten material into a mold.

Injection molding can be used with a variety of materials, including thermoplastics, thermosets, and elastomers.

Injection molding offers many benefits, including high production rates, low labor requirements, and the ability to produce parts with complex shapes and features.

Yes, injection molding can be used to produce parts with different colors or textures by incorporating colorants or additives into the molten material before it is injected into the mold.

The process for ordering an injection mold from JSJM Technology begins with a consultation to discuss your specific needs and requirements.

Copyright © ©Copyright 2024 JSJM Technology Co., Ltd. all rights reserved - Privacy policy