ONE-STOP PRODUCT DEVELOPMENT SERVICE

Step modules are made according to manufacturing steps

Our engineers team helps customers with prototyping. And improve the design from the view of production! 3D printing for proofing before making the mold.

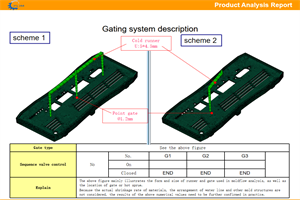

Before making the mold, engineer will provide professional and detailed DFM Report and Moldflow Analysis Report to customer. It Help engineers and customers improve the success rate of development!

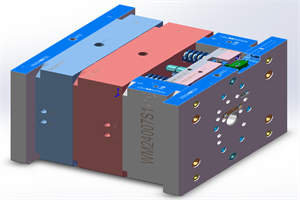

We will confirm the 3D mold drawings with the customer, and the customer will see every accurate mold parts clearly!

Professional mold department is responsible for manufacturing every mold part and finally assembling them into a complete mold! Precision CNC machines from Japan can achieve ±0.001 tolerance!

100 employees injection molding department, 50 sets of 80-560 tons of injection molding machines, 24 hours of uninterrupted production! We always provide customers with high efficiency, high quality, low cost production services!

Owning ten assembly lines and more than 300 assembly employees. We can help customers improve production efficiency, reduce production costs and improve product quality. We let customers rest assured to receive complete and perfect products!

Not only Plastic Parts, our other two subsidiaries provide metal parts include stamping metal parts, die-casting metal parts, sheet metal parts, etc, and precision connectors as well as kind of PCBA boards. We have powerful suppliers resource and reliable quality control department to produce all components that customers require!

We strictly adhere FIFO method. Make sure the label matches the goods. Ensure that the product will not be damaged during transportation. Pack molds in non-fumigating wooden cases. Pack products in KKKKK cardboard boxes! And according to the actual situation, we will make blister packaging!

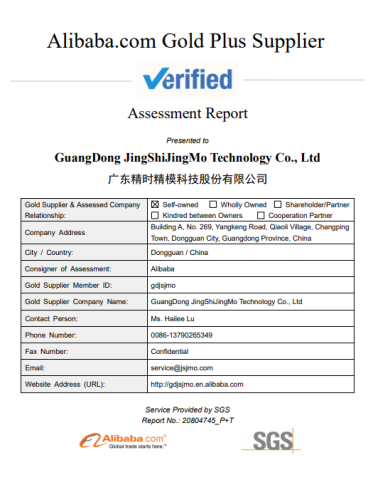

CERTIFICATE

EXHIBITION

Copyright © ©Copyright 2024 JSJM Technology Co., Ltd. all rights reserved - Privacy policy