The Explained Complex Metal Shapes Of Metal Injection Molding

Metal injection molding (MIM) is a manufacturing process which uses metal powder and binder material to create complex shapes and components. Let’s look at the MIM process itself:

Preparation:Metal powders with an average size of 15-30 micrometers are mixed with a binder material such as wax or polymer. The combination can thus be injected into the mold using the binder as a carrier.

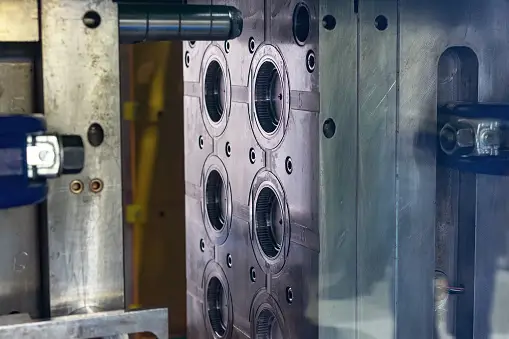

Injection Molding:The mixture is then injected into a mold under high pressure, just like in plastic injection molding. This holds together the metal powder by means of the binder, thereby forming a green part.

Debinding:Finally, this green part is removed from the mold and subjected to thermal or chemical treatment that removes its binder but leaves behind sintered metal parts.

Sintering:In this case, the resultant green part is heat treated in order to fuse together metal powder particles until they form a tough and compact final product.

Post-Processing:To achieve desired finish and properties, any necessary post-processing steps may include machining, polishing or heat treating among others.

There are several advantages ofmetal injection moldingover traditional methods of manufacturing. It makes production of intricate details possible for complex shapes that would have been difficult if not impossible through alternative techniques. The process demonstrates high precision, repeatability as well as consistency regarding dimensional accuracy and material characteristics. Furthermore, it is cost effective for small production runs while it can produce parts made from different materials including ferrous/non-ferrous alloys.

For instance, automotive industry medical sector consumer goods companies aerospace.Metal Injection Molding has found application in various industries including automotive industry medical field consumer goods companies aerospace; particularly suitable for parts that need high tolerance levels complicated geometries intricate details…. Thus Metal Injection Molding (MIM) has become one of the principal technologies for producing highly accurate components with excellent performance that meet stringent design criteria.