Injection products flash, overflow, burrs and other solutions

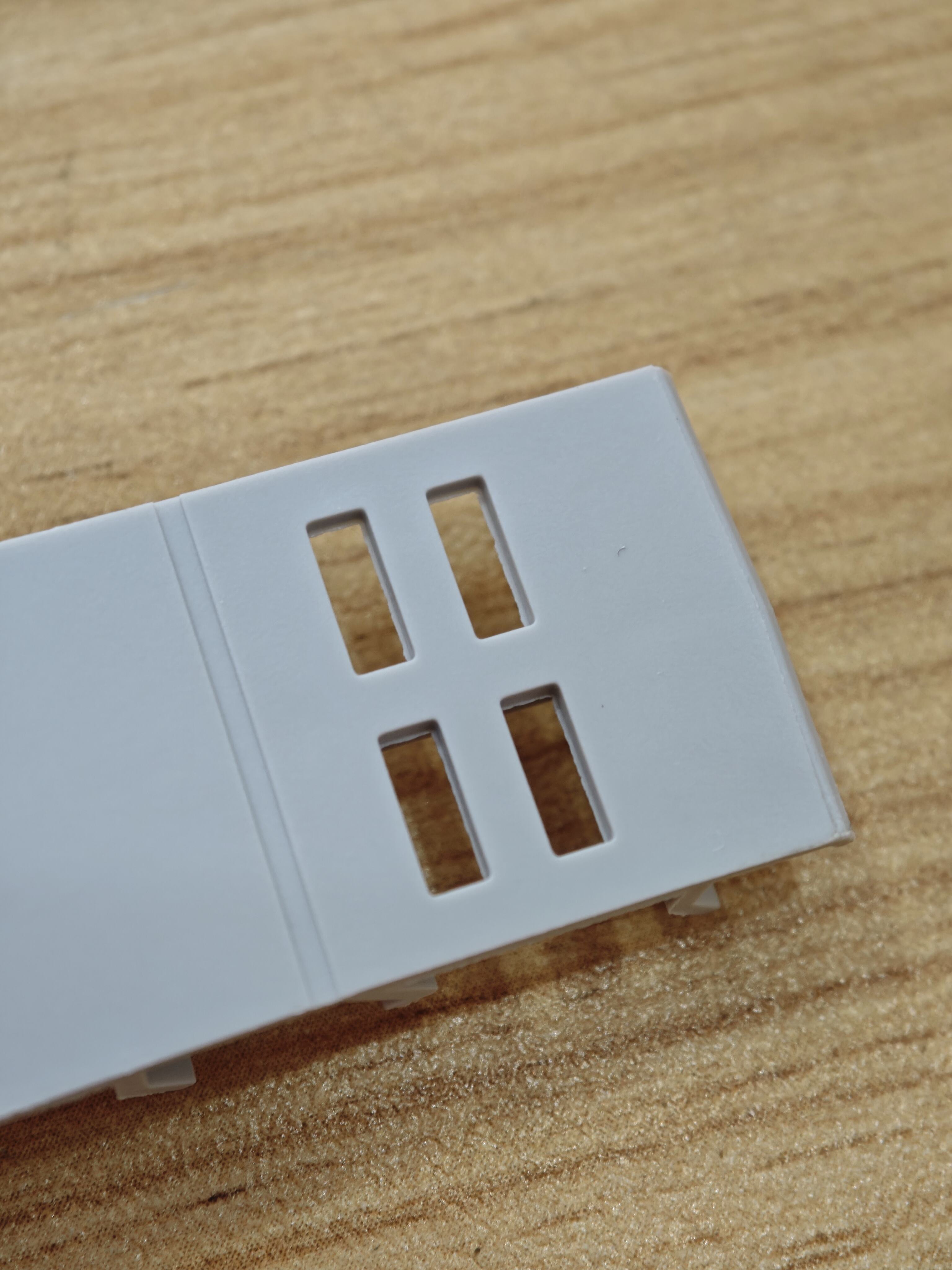

The top, also known as flash, overflow, overflow, etc., mostly occurs in the parting position of the mold, such as: the parting surface of the mold, the sliding part of the slider, the gap of the insert, the porosity of the ejector rod, etc. If the overflow is not solved in time, it will be further expanded, thus forming a local collapse of the imprinting mold, causing permanent damage. The tip of the gap of the insert and the pore of the ejector rod will also make the product stuck on the mold, affecting the release of the mold.

The tip is essentially the excess left on the product after the gap between the plastic material entering the mold and the matching part is cooled. To solve the problem of the cap is very simple, that is, to control not to let the melt into the mold to fit the gap.

Plastic melt into the mold to fit the gap, there are generally two cases: one is the mold fit gap is originally large, colloids are easy to enter it; The other case is that the mold gap is not large, but it is forced into it because of the pressure of the molten colloid.

On the surface, it seems that as long as the manufacturing accuracy and strength of the mold can be completely solved. It is necessary to improve the manufacturing accuracy of the mold, reduce the matching gap of the mold, and prevent the melting colloid from entering. However, the strength of the mold, in many cases, can not be infinitely strengthened, strengthened to any pressure, the colloid can not burst into it.

The production of the top has both mold and process reasons. Check the reasons for the process, first check whether the clamping force is enough, only to ensure that the clamping force is enough, when the tip is still generated, check the reasons for the mold.

Check whether the clamping force is sufficient:

1) Gradually increase the injection pressure, with the increase of injection pressure, the tip also increases correspondingly, and the tip is mainly generated on the parting surface of the mold, indicating that the clamping force is not enough.

2) Gradually increase the clamping force of the injection molding machine, when the clamping force reaches a certain value, the cap on the parting surface disappears, or when the injection pressure is increased, the cap on the parting surface will no longer increase. This value of mode-locking force is considered to be sufficient.

Check whether the mold manufacturing accuracy caused by the method:

With a lower material temperature, a lower filling speed, and a lower injection pressure, the product is just full (the product has a slight shrinkage). At this time, it can be considered that the ability of melt to break into the mold gap is very weak, and if the tip is generated at this time, it can be judged that it is a problem of mold manufacturing accuracy and needs to be solved by repairing the mold. It may be considered to abandon the use of technological methods to solve the generation of the tip.

It should be noted that the above "three low" conditions are indispensable, high material temperature, faster filling speed, and higher injection pressure will cause the local pressure of the mold cavity to increase, enhance the ability of melt to break into the mold with the gap, and expand the mold to produce a cap, although the product is not satisfied with the glue at this time.

The analysis of the causes of the tip is based on the premise that the clamping force is sufficient. When the clamping force is insufficient, it is difficult to analyze the causes of the tip. The following analysis is based on the case of sufficient clamping force, please pay attention to the reader.

According to the several situations in which Pifeng appears, the possibility of Burrs:

The first case:

As mentioned above, in the case of low temperature, low speed and low pressure, when the product is not satisfied with the glue, the tip has been produced. The main reasons may be: the mold manufacturing precision is not enough, the cooperation gap is too large;

The second case:

When the product is just full of glue, the local shrinkage phenomenon occurs, and there is no tip. When the injection pressure is increased to improve the local shrinkage of the product, the tip is generated. Possible causes are:

1) Material temperature is too high. The high temperature of the material, the low viscosity of the melt, the good fluidity, the stronger the ability of the melt to break into the mold with the gap, will lead to the emergence of the tip.

2) The injection speed is too fast, and the injection pressure is too large (resulting in supersaturation of the fill). Too fast speed, too much injection pressure, especially too much injection pressure, will enhance the ability of melt to burst into the mold with the gap, resulting in the emergence of a tip.

3) The fluidity of plastic is too high. The better the fluidity of the plastic, the lower the viscosity of the melt, and the stronger the ability of the melt to drill into the mold with the gap, it is easy to produce a tip. When the mold production has been completed, the depth of the exhaust groove of the mold and the cooperation gap of the mold have been finalized, and another kind of plastic with good fluidity is produced, it will produce a cap.

4) The strength of the mold is insufficient. When the design strength of the mold is insufficient, when the mold cavity bears the pressure of the plastic melt, it will deform and expand, and the colloid will burst into the gap of the mold, producing a cap.

5) Unreasonable product design. The local glue site of the product is too thick, and too much shrinkage during injection molding will lead to local shrinkage. In order to adjust the problem of local shrinkage of products, it is often necessary to use higher injection pressure and longer injection time to fill and maintain pressure, which results in insufficient mold strength and deformation, resulting in a tip.

6) Mold temperature is too high. High mold temperature can not only make the plastic maintain good fluidity, small pressure loss, but also reduce the strength of the mold, which will also lead to the generation of the tip.

The third case:

It is the most frequently encountered problem in injection molding production, which can not be solved by all process means, and it is the biggest problem for injection molding technicians. For this situation, the most important means is to fix the mold. The solutions are:

1) Product local glue reduction. The local shrinkage of the product is reduced, and after the glue site is reduced, the product shrinkage problem can be improved, the injection pressure will be reduced, the mold deformation will be small, and the tip can be suppressed. This is the most effective and commonly used method.

2) Add glue points. Increasing the pouring point can reduce the injection molding process, reduce the injection molding pressure, the pressure on the mold cavity will be reduced, and the generation of the tip can be effectively solved. Increasing the injection point, especially in the shrinking position of the product, can have an immediate effect on reducing the injection pressure of the mold cavity. It is also one of the more commonly used means.

3) Strengthen the mold part. Sometimes the deformation of the template can be strengthened by adding a brace between the moving template and