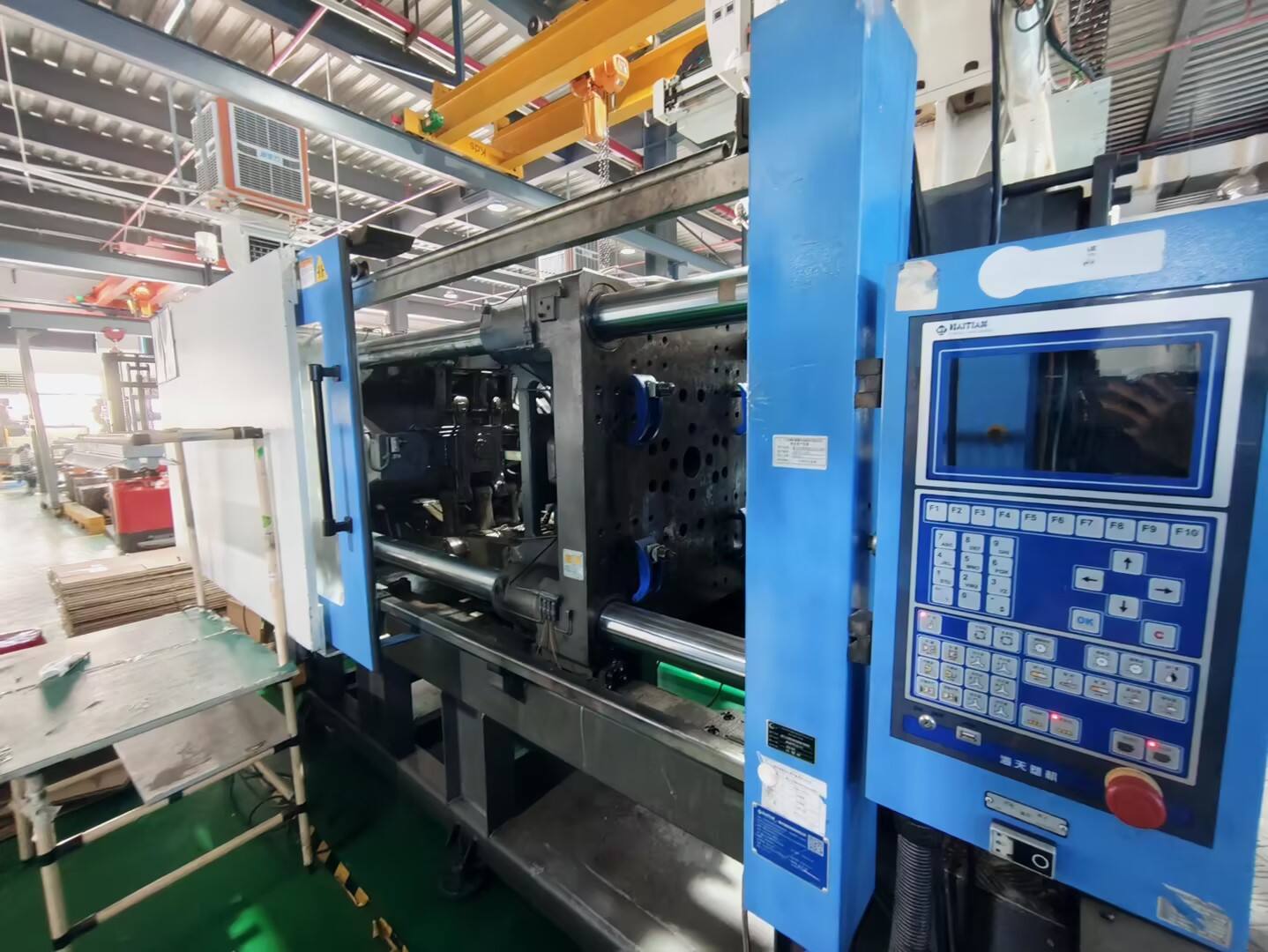

Injection molding machine electrical system, oil pressure system, mold locking part, injection part maintenance points

Injection molding machine production is generally 24 hours of operation, for a long time in the working state of the machine, we must do a good job of maintenance work, and strive to find problems before the machine failure to solve the problem. Otherwise, once the machine fails, it must be stopped and repaired, affecting production.

Therefore, it is particularly important to do a good job of maintenance of the injection molding machine. To do a good job in the maintenance of the injection molding machine, the maintenance content must be classified according to the frequency of possible failures: the highest frequency content is included in daily maintenance, the frequency is slightly lower in weekly maintenance, and so on, and then the monthly maintenance and annual maintenance work content is classified.

After the maintenance content is determined, it is best to arrange a special person to be responsible for ensuring that the maintenance work is effectively implemented in accordance with the planned arrangement. Each time the maintenance work is completed, the necessary records must be made so that the evaluation of the machine in the future work has a basis.

Electrical system maintenance

(1) When checking the high voltage element in the machine, if not necessary, the main power supply should not be turned on.

(2) When replacing the mold, do not let the cooling water into the electric control box.

(3) Check whether the temperature in the electric control box is too high, which will affect the normal work and service life of the electronic board.

(4) When changing the relay, the specified voltage relay should be used.

The hydraulic oil temperature of the injection molding machine should be maintained between 30-55 degrees Celsius. If the oil temperature exceeds 60 degrees Celsius, the following problems will occur:

(1) The hydraulic oil deteriorates due to oxidation.

(2) The viscosity of the hydraulic oil is reduced, resulting in damage to the oil pump, oil leakage and pressure drop, and the efficiency of the whole machine is reduced.

(3) Accelerate the aging speed of oil seal.

(4) Prevent cooling water from leaking into the system tank, pay special attention to check whether there is water leakage inside the oil cooler. Clean out the inside of the cooler every six months or so.

(5) The injection molding machine must be replaced once every 3000-4000 hours of work, and the new and old oil can not be mixed when replacing the oil, and the filter in the tank should be twisted off for cleaning.

(6) Because the valve spool is blocked by foreign objects, the valve spool should be removed and cleaned with diesel or kerosene (or immersed in clean hydraulic oil), and then compressed air is used to remove foreign objects.

Maintenance of mold locking parts

(1), the clamping part of the hinge working life is very long, but each moving part should be properly lubricated, otherwise the hinge will wear and reduce the life.

(2) Keep the four pull rods clean.

(3) Keep the sliding feet and rails of the moving template clean and lubricated.

(4) Avoid using molds close to or exceeding the working pressure.

(5) When adjusting the mode, the express mode locking speed cannot be used.

(6) Control the stroke position of the mode locking action in the most appropriate position to reduce the impact of the mode locking to the machine.

Maintenance of the injection part

(1) Keep the guide bar lubricated and clean.

(2) Keep the surface of the shooting platform clean and dry.

(3) When using the material return, the hopper magnetic frame must be added in the hopper to prevent metal debris from entering the melt tube.

(4) The barrel temperature reaches the set temperature for about 3 minutes of reproduction (to ensure that the raw materials in the barrel are completely softened) to prevent damage to the screw and transmission system.

(5) When the barrel does not reach the preset temperature, do not start the melt motor, and do not use the reverse cable (loose) action to avoid damage to the rotating system components.

(6) Use the correct plastic replacement and cleaning method provided by the plastic supplier.

(7) Periodically check all parts of the shooting table, tighten the loose parts, and ensure the balanced installation of the two injection oil cylinders to avoid damage to the oil seal of the injection oil cylinder, oil cylinder, piston rod and other damage.

(8) When the melt temperature is normal and there are constantly black spots or discoloration of the melt, it should be checked whether the thrust ring and thrust ring of the injection screw are damaged.