Fundamental Characteristics Influencing The Injection Molding Of Plastics

The injection molding of plastics, generally, is a manufacturing method that creates components of complicated shapes all in one process and meets high-quality requirements. Nonetheless, the successful and effective implementation of this practice may depend on the key factors that should therefore be comprehended in order to optimize production, as well as the outcome expected.

Plastic Material Selection

Plastic materials selection is regarded as a deficiency plastic or metalqualified within the process of selection for injection molding firms. As a matter of fact, any plastic has its own characteristics which can include melt flow rate, viscosity melt, and thermal plastic performance among others. Thus, selecting a material with a required type of melt is crucial since it will not only determine the nature of the end products but also the molding techniques and the tools required as well. Injection molding materials include ABS, polycarbonate, and nylon-type materials each with their specific properties for meeting user requirements.

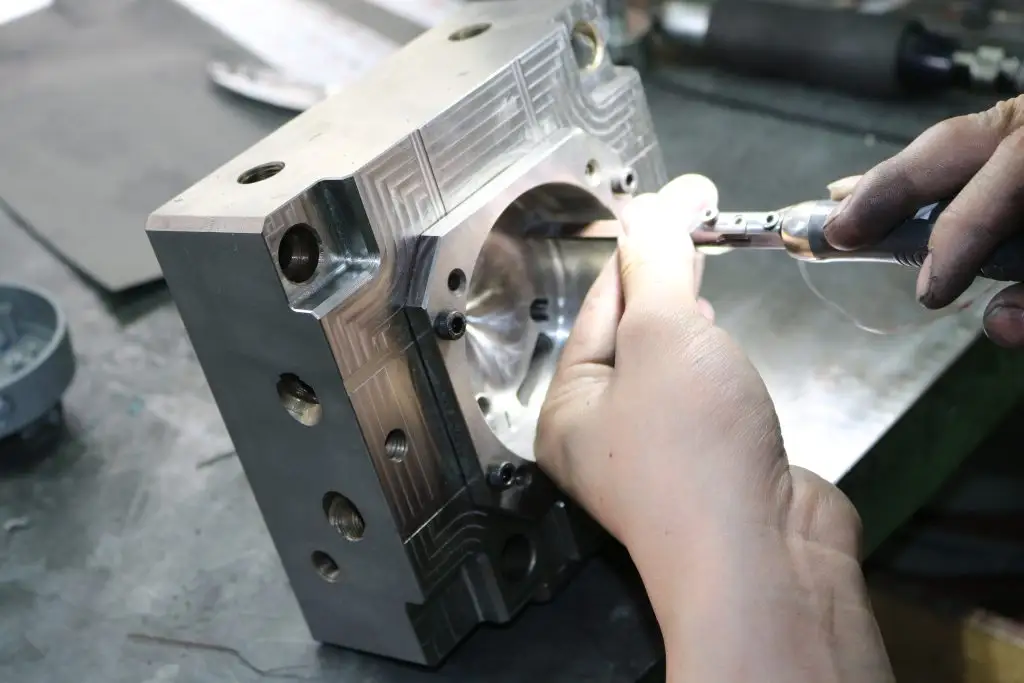

Mold Design

Mold design is integral in the plastic injection molding process. A properly constructed mold helps ensure that there is optimum flow of the molten plastic, reduces defects, and shortens the overall cycle time. Gate location, cooling channels, and venting are some of the parameters that should be taken into consideration during mold design. The efficiency of the injection process and the quality of the parts produced are interrelated and are impacted by the mold design. Adequate cooperation with mold designers can enhance production performance.

Processing Conditions

Temperature, pressure, and injection speed are some of the factors that have an impact on the parts produced by molding processes and take place during the injection molding cycle. It is important to develop the best possible processing conditions so that the plastic will flow into the mold cavity in the desired manner, fill the cavity, and then solidify appropriately. Warping, sink marks, and short shots for example may be minimized by altering the processing conditions. These conditions need to be supervised and adjusted on a consistent basis in order to ensure that the desired product quality is realized.

Cycle Time Optimization

Cycle time, or the total time to design, build, and test a product or components of such, is equally important in the injection molding of plastics and rapid prototyping. The cycle time in practical terms always goes hand in hand with the product cost, there are a number of elements and factors that impact the resulting cycle duration and thus need to be improved and well understood. Key elements impacting cycle time include the injection speed, cooling time, and mold temperature. Such efficiently integrated techniques enable increased production throughput and resource concentration, thereby decreasing product cycle times.

To end with, quite a few of the factors affecting the injection molding of the plastics include materials used, design of the molds, design of the processing conditions, as well as time optimization. Controlling and knowing these factors is essential for quality production and for the efficiency of the operations.